Local designers and developers have a habit of being stressed with their work. It is a natural occurrence that emerges through internal and external forms of pressure.

Although that anxiety might not disappear anytime soon, there are utilities and resources that can allow professionals to relax and focus on their core duties.

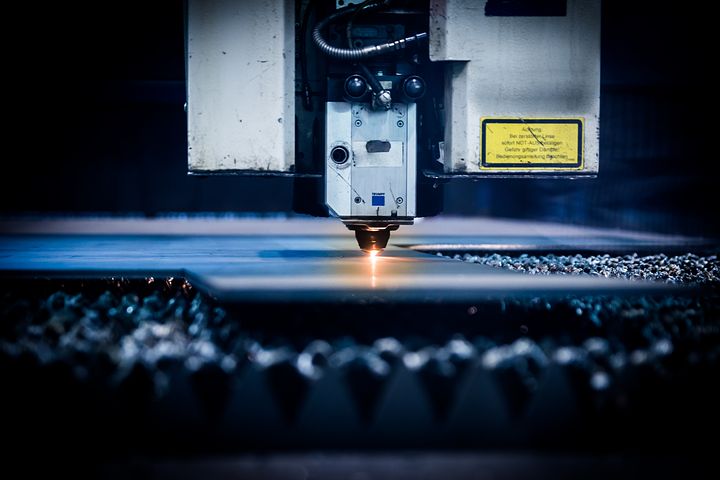

One of those components will be found with a laser cutter program, giving practitioners the means to undertake their activities in a stress-free fashion.

Cutters Are Easy to Find

One of the benefits of working with a laser cutter system is the capacity to actually find a model that works. This activity alone can create a lot of stress for designers and operators who feel like they are being left behind the competition and falling behind schedule with their constituents. From major retail chains to local outlets and private sellers respectively, there is a wide variety of locations where these program can be obtained for the short or long-term.

Cutters Can Be Affordable For Most Operators

A key area that causes a lot of stress for practitioners is the cost of investment. Given the size and scope that is on display with a laser cutter design, they are not considered cheap utilities. Thankfully there are sellers who extend loan and lease agreements as well as servicing provisions and warranties to protect the value of the product. That is why it is affordable for most participants no matter what niche they happen to operate in.

Cutting Results Are First-Class

The pressure that is placed on the shoulders of designers and developers with their work is extensive. Even when operators dedicate a huge amount of time and energy with these materials, they have to ensure that their production stands up to any form of scrutiny from the client. This is where a laser cutter system really shines, offering a model that works within a margin of error of 0.0005 inches per application.

Programming is Automated

A common issue that many sole contractors and specialists have with their work is trying to keep their concentration levels perfected and to avoid human error. That is easier said than done when traditional utilities have to be manually engaged. It becomes a reality when a laser cutter model is introduced, empowering individuals and team members to automate their material manipulation through a computer apparatus. Everything can be designated at a touch of a button.

The Work is Safe

A genuine knock-on benefit of the no-contact approach with a laser cutter is being able to protect user safety. It is understandable how stressful these manufacturing and development environments can be with tools that can cause serious injury or death. That is why these modern systems take enterprise to another level, allowing participants to be relaxed with their programming without putting themselves in harm’s way.

The Material is Adaptable

Local operators know that they have to be adaptable when it comes to the materials that are in play with these modern structures. That is why cutter brands are so beneficial to specialists, allowing them to utilise woods, metals, ceramics, plastics, rubber and other components within the scope of the same system. No longer do professionals have to stress about investing in different models for the sake of overseeing their projects.

Customer Service Assistance is Available

There is no shame in reaching out for assistance, especially when these laser machines are sold from reliable traders and industry outlets who have their customer’s interests at heart. Whether it is consultations that give users the chance to see their assistance up close or guidance through phone calls and website messaging systems, there will be representatives available who can help clients to optimise their experience with the laser cutter investment.